Choosing the Right Implant Analog for Accurate Restorations

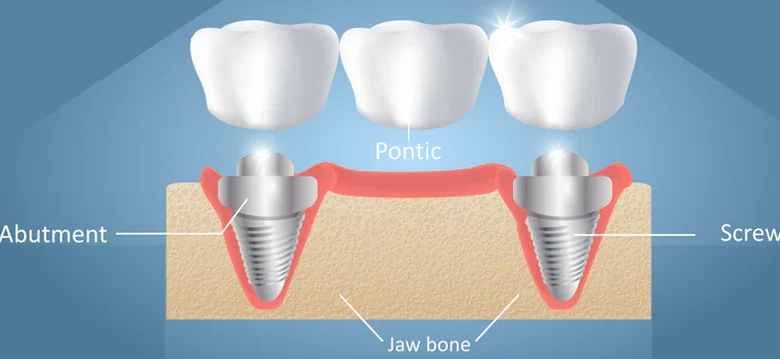

Choosing the right implant analog for your dental lab cases is a crucial step in ensuring the accuracy and success of implant restorations. Implant analogs serve as the foundation for creating precise models that replicate the exact position and angulation of the actual dental implant in a patient’s mouth.

Selecting the wrong type—or using low-quality analogs—can lead to poor-fitting restorations, increased remakes, and dissatisfied clients.

Dental labs working with multiple implant systems often struggle with compatibility, as different manufacturers have varying designs and connection geometries.

Understanding the types of implant analogs available, their compatibility factors, and how to select the right one for each case can make all the difference in the precision of your restorations.

Understanding the Different Types of Implant Analogs

Implant analogs are designed to mimic the actual implant fixture, allowing dental technicians to work with models that represent the exact positioning of the implant in the patient’s mouth. However, not all analogs are the same.

-

Lab Analog vs. Digital Analog

- Lab Analogs: Traditional analogs used for physical stone models. These are essential for creating accurate implant restorations in conventional workflows.

- Digital Analogs: Designed for 3D-printed models, these analogs integrate seamlessly with digital workflows, improving efficiency and precision.

Internal vs. External Connection Analogs

- Internal Connection Analogs: Feature a deep connection within the implant fixture, improving stability and reducing micromovement.

- External Connection Analogs: Have a flat-topped connection sitting above the implant fixture, used in older implant systems. These require more precise handling due to a greater risk of rotation and misalignment.

Brand-Specific vs. Universal Analogs

- Brand-Specific Analogs: Designed to match a specific implant brand’s specifications precisely, ensuring a perfect fit.

- Universal Analogs: Compatible with multiple implant systems, offering greater flexibility for labs working with various implant manufacturers.

Key Factors to Consider When Choosing an Implant Analog

1. Compatibility with the Implant System

One of the most important factors is ensuring the analog is compatible with the implant system being used. Some implant systems have proprietary designs, requiring brand-specific analogs. Others can accommodate universal analogs, which offer versatility without sacrificing precision.

2. Precision and Manufacturing Quality

Poorly machined analogs can introduce small discrepancies that lead to major fitment issues. High-quality CNC-machined analogs, like those from 32DentalLab, ensure tight tolerances and accurate replication of the implant position. Precision is key to avoiding costly remakes.

3. Material and Durability

Implant analogs are typically made from stainless steel or titanium, ensuring durability during the model-making process. Choosing high-quality materials prevents distortion and ensures longevity, especially in digital workflows where repeated use of analogs is common.

4. Workflow Integration (Traditional vs. Digital Dentistry)

If your lab uses a fully digital workflow, selecting digital analogs that integrate with 3D-printed models is essential. Conversely, if you work primarily with traditional stone models, choosing traditional lab analogs remains the best option. Some labs operate in a hybrid environment, requiring both types.

Why High-Quality Analogs Matter for Your Lab

Using subpar or incorrect implant analogs can result in poorly fitting restorations, patient discomfort, and an increase in costly remakes. By choosing versatile implant analogs compatible with leading brands, labs can ensure consistency, reliability, and greater client satisfaction.

Labs that prioritize precision-engineered implant components experience fewer adjustments, smoother workflows, and better long-term results for both dentists and patients.

32DentalLab’s premium implant analogs offer unmatched accuracy and compatibility, making them the go-to choice for modern dental labs seeking reliable solutions.

Conclusion

Selecting the right implant analog isn’t just a technical decision—it’s a choice that impacts the overall success of an implant case. Whether you’re working with traditional stone models or digital workflows, ensuring you have the correct analog for the specific implant system is essential for precision and predictability.

For dental labs seeking high-quality, precision-milled implant analogs, 32 Dental Lab offers a range of options designed for compatibility, accuracy, and reliability. Investing in the right implant analogs will not only improve your workflow but also enhance the overall quality of your restorations.