Nail

The whole nail totally inundate into a tank of liquid zinc

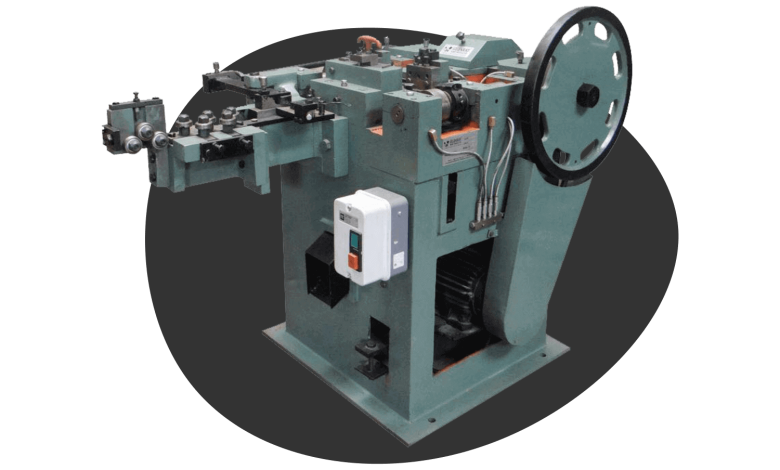

Hot Dipping in Molten Zinc. Hot dunking nails in Molten Zinc recognize by most specialists as the most ideal way to apply a weighty uniform covering to nails. In this cycle. The nails totally inundate into a tank of liquid zinc. Like french-searing potatoes. This not just gives an external covering of unadulterated zinc. Yet additionally gives an industrious internal covering of zinc-steel composite. wire nail making machine

Aroused nails

Aroused nails additionally safeguarded by a second dunk into the defensive zinc to block pinholes or defects. And to expand how much zinc on each nail. This restrictive handling by totally mechanized hardware protects both a weighty. Uniform zinc covering. And clean strings for high holding power.

Definitive assessment

Excited nails have breezed through a definitive assessment without a hitch – north of 85 years of field administration with a record unrivaled by some other zinc-covered nail maker. No big surprise manufacturers and project workers say that nails. There are the best steel-put together nails with respect to the market. Practical, simple driving, and particularly intended to appropriately apply a wide range of current material, siding, trim, and decking. Nails with zinc chips pivot in a barrel in a heater.

Tumbler or Barrel Hot Galvanizing

Hot-Galvanized nails are the sort most frequently created by huge steel plants. Sadly, the expression “hot-stirred” nails befuddle by many individuals with hot-plunged nails. And don’t offer a similar execution as do hot-plunged nails. Hot-electrifies nails are covered by sprinkling zinc chips on cool steel nails in a barrel, then, at that point, pivoting the hot barrel in a heater to dissolve.

Liquefying zinc

And appropriate the zinc. The liquefying zinc washes off on the nails – to some degree like buttering popcorn – and similarly a few nails get overabundance zinc and some tiny. One trouble is that the strings of ring and screw knife nails will quite often top off with zinc during this cycle. Likewise, it is challenging to store sufficient zinc on top of and under the nail heads. Since this interaction basically doesn’t create a uniform nature of covering, it has been deserted totally at the Maze Nails plant. We make just hot-plunge nails. Went in for seconds excited nails.

Mechanical Plating

Mechanical plated nails, likewise called peen plated nail. There are somewhat new advancement including moving virus nails around in a barrel with zinc dust. Small glass and an activator liquid. The barrel pivots and the BB’s sledge or peen the zinc dust onto the nails. Once more, the outcome moderately perfect strings.

Store of zinc

However ordinarily just a flimsy store of zinc which is additionally buttressed by inundation in a chromate wash. Nails engineers this interaction. With the creators until their own tests shown. That our elite going in for seconds process unrivale for covering outside nails.

Nail put into an electrolytic arrangement

Electro-plating of nail perform by setting them in a crate into an electrolytic arrangement so a flimsy film of zinc is stored by an electrical flow from zinc anodes onto the outer layer of the nails. In spite of the fact that electroplated nails are wonderful and sparkly, it isn’t plausible monetarily to develop a sufficiently weighty covering to make this sort of nail reliably erosion safe for open air use.

Slender zinc

The slender zinc covering before long oxidizes away so that electro-plated nails regularly rust rapidly upon openness to the climate. simply ask any accomplished siding tool. So, plated nails have great holding power from clean strings. However, they don’t have the weighty zinc covering expected to abstain from rusting and staining. We “two-fer”. Excited nails.

Demonstrated

There is suggests the interaction demonstrated by such countless long periods of real field openness to be the most effective way to place defensive zinc on a solid steel base nail – hot-plunging! We market our hot-plunged nail line under the brand name. The stirred nail we assurance to be hot-dunked two times in liquid zinc by our mechanized process.

Stirred nails

Be careful with supposed Hot-Dip excited nails. That really produce using hot-plunge electrifies wire. It stirred nails twofold hot-dunked in liquid zinc. After the nails cut and strung so the thick, uniform zinc-covering is solid over the whole surface of the nail.

Excited nails

A few organizations cut corners by assembling their excited nails from hot-plunge stirred wire and guarantee. They meet the As their stir nail slice to length. And the heads frame in the nail machine. The zinc-covering crush. And fan out meagerly on the main piece of the nail allowed to stay uncover after application.

Trustworthy erosion obstruction

Those nails don’t offer a similar level of trustworthy erosion obstruction as evident hot-plunge stirred nails. Along these lines. Careful with makers who guarantee this strategy meets the for hot-plunge electrifying to astutely get around construction regulations. And industry suggestions for hot-plunge excited nails.

Wire Rope Lays

The decision of center and making of the strands are the easiest yet most fundamental pieces of wire rope development. Wire rope lays, the strategy to breeze the strands. It is more intricate and includes a few decisions.

Lay is a term used to depict three of the fundamental qualities of wire rope:

bearing, relationship, and direct distance. The strands can fold over the center going right or left. Profoundly and the wires inside the strands.

Kinds of lays

Customary or Ordinary

In a customary lay, the wires and strands winding in inverse headings. With a right hand standard lay, the wires winding to the left and the strands to the right. In the left hand standard lay, the wires winding to the right and the strands to the left. This sort of lay is not difficult to deal with however breaks down rapidly in light of the fact that the crown wires are in touch with the bearing surface.

Wires

The wires and strands winding in a similar course with right hand. Lay being the most well-known. The wires in a Lang lay seem to run corresponding to the middle line of the rope. The trouble with Lang lay wire ropes is taking care of since they will generally crimp. Bend, and smash.

Mild Steel Wires

Walking ahead with time and leading the item blend, we produce our esteemed re-moved Mild Steel Wires, gigantically open across the seas, emblazoning our importance and our worldwide mark.

Steel wire pole

These Mild steel wires is drawn through ‘chilly drawing cycle’s utilizing steel wire pole, getting from astounding quality natural substance of our own auxiliary organization. Wire Rod is first D-scaled with the assistance of Double plain descaler free of gentle scale. And afterward the cleaned wire pole is handled further to go through various kicks the bucket and drums with a normal decrease of 25% to ultimately accomplish the designated eventual outcome size and afterward it take in group state of proper individual castings.

Knowledge

Harvesting upon the mechanical venture with for knowledge. Its yearly limit is 1.2 lac metric tons. Sends out is on runway running with a significant lump of our current deals guaranteeing take off round the corner. Our Steel wires track down sincere appreciation across framework areas, enduring all weights of developments. Such super completion fortified Binding wire and Nails wire excited to a great extent in development industry. And spiked metal in fencing and for some such assortments of utilizations.

Read more: Malaysia Tourist Attractions That Are Perfect For Senior Citizen